INCONEL ALLOY 600 TUBES, INCONEL 625 PIPES SUPPLIER, ALLOY 625 TUBING STOCKISTS, SUPPLIER, ALLOY 600 TUBES

ALLOY 600 PIPES SUPPLIER, UNS N06600 TUBING, UNS N06625 TUBES SUPPLIERS, WNR 2.4816/2.4856 PIPES EXPORTER

SEAMLESS ALLOY 600 TUBES, ALLOY 625 WELDED PIPES, UNS N06600 / UNS N06625 SEAMLESS TUBES TUBING MOST ACCLAIMED SUPPLIER

Alloy 600/625 Tubes | Inconel 600/625 Pipes | UNS N06600/N06625 Tubing’s | Alloy 600/625 Seamless Pipes | Alloy 600/625 Tubes Supplier

Alloy 600/625 Pipes, Inconel 600/625 Seamless Pipes & Tubes Available in Size range: 1/2” Sch 5 through to 6″ Sch 40

High Quality Inconel Alloy 600/625 Pipes Available for Immediate Delivery – Call On +91-22-67496309 | [email protected]

Silver Tubes is an eminent manufacturer of Inconel Alloy 600|625 Pipes, Tubes which has a solution of excellent workability and high strength and is readily weldable. Inconel 600 tubes pipes are used for heat components, in food and chemical processing, for sparking electrodes, and in nuclear engineering. These pipes are an alloy of nickel-chromium with best corrosion resistance at high temperature, acid corrosion, and oxidation by high-purity water. These pipes tubes used in aerospace applications and the chemical industry.

About Inconel Alloy 600|625 Pipes, Tubes:

The tools of Inconel Alloy 600|625 Pipes and Tubes are sharp and

have precise geometry. The alloy of 600|625 Pipes and Tubes

provide corrosion resistance and carburization resistance up to

2000 degree F used at inflated temperature inactive

applications. The pipes and tubes are used for equipment

chlorination up to 538 degrees C, and also in titanium dioxide

machines. The versatility of these tubes and pipes has got to

its use in several applications including temperatures for

cryogenic to over 2000 degree F.

The typical mechanical properties of 600 pipes and tubes are its

tensile strength, elongation, melting point, and yield

strength.

The general applications of About

Inconel Alloy 600|625 Pipes, Tubes

are:

• Ethylene dichloride crackers

• Barge lines

• Furnace trays

• Carburizing environments

• Tank truck liners and more.

The products of silver Tubes are made from the perfect quality

of raw material, and they provide various designs to suit many

requirements of the customer. We used modern technology and

stable efforts to develop current skills to increase production

and improve quality.

Inconel Alloy 600/625 Pipes Tubes Manufacturing

Inconel Alloy 600/625 Pipes Tubes Testing

Inconel Alloy 600/625 Pipes Tubes Packaging

Call Us for Best Prices for Inconel Alloy 600/625 Pipes & Tubes!

Inconel Alloy 600/625 Seamless Pipes/Tubes for Chemical Industry, Pulp, & Paper Manufacturing, Heat Exchangers, Process Piping

Mill Test Certificates | NABL Approved Lab Test Reports | 100% PMI | Spectro Chemical Analysis Test for Alloy 600/625 Pipes and Tubes

Worldwide Distributor of Alloy 600/625 Tubing, Inconel 600/625 Pipes! Exports is Our Specialty!!!!!

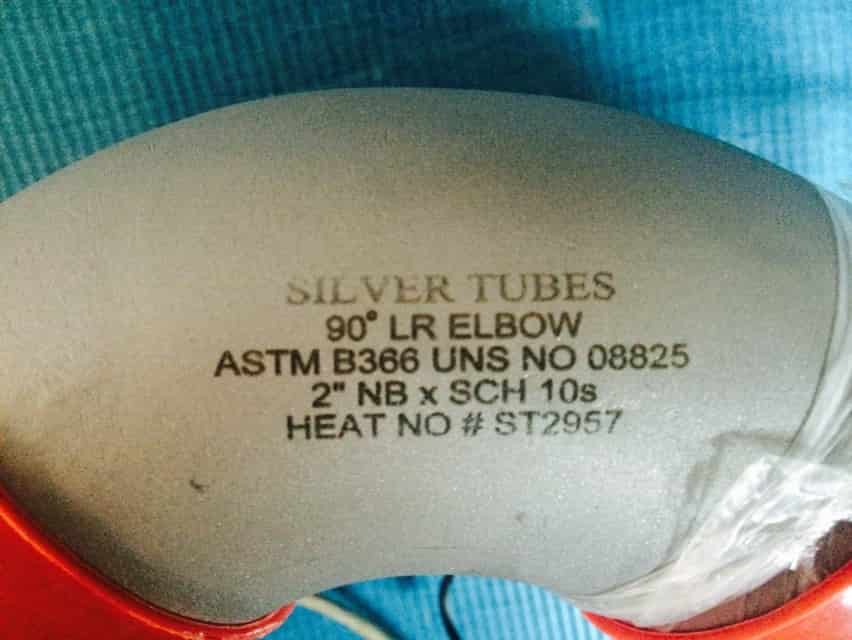

Inconel 825 Elbow

|

Nickel Alloys |

Tradename |

UNS no. |

Werkstoff No. |

Density (8.8 g/cm3) |

|

Alloy 600 |

Inconel 600 |

N06600 |

2.4816 |

8.42 |

|

Alloy 601 |

Inconel 601 |

N06601 |

2.4851 |

8.2 |

|

Alloy 625 |

Inconel 625 |

N06625 |

2.4856 |

8.44 |

|

Alloy 718 |

Inconel 718 |

N07718 |

2.4668 |

8.19 |

Inconel 600/625 Seamless Pipes, Alloy 600/625 Tubing’s, UNS N06600/N06625 Pipes Exporter, Supplier, Distributor

TENARIS DALMINE-ITALY, SUMITOMO-JAPAN JFE-JAPAN, V&M-GERMANY/FRANCE, HYUNDAI-KOREA, PRODUCTOS TUBULARES – SPAIN, INOX TECH - ITALY, DMV STAINLESS, TUBACEX-SPAIN, VALCOVNY TRUB-CZECH MITTAL, STEEL-ROMAN, SANDVIK-SWEDEN, TUBOS REUNIDOS-SPAIN, BENTLER -GERMANY, PIETRA – ITALY, TENARIS – TAMSA, KOBE STEEL – JAPAN, US STEEL – USA, MITTAL NOVA HUT-CZECH, MITTAL ISCOR - S.A., SEAH STEEL – KOREA, PLYMOUTH TUBE CO. – USA, NIPPON STEEL, ARCELLOR MITTAL – SOUTH AFRICA, VOLZHSKY - RUSSIA, NIPPON STEEL & SUMITOMO METAL CORPORATION, DOCKWEILER - GERMANY, PEXCO - USA, SPECIAL METAL WIGGINS LTD, MAHARASHTRA SEAMLESS LTD - INDIA, JINDAL SAW LTD - INDIA, ISMT – INDIA, LS METAL - KOREA, RATNAMANI - INDIA, SANYO SPECIAL STEEL, MAN INDUSTRIES INDIA LTD, EISENBAU-KRAEMER GERMANY, ZENITH BIRLA LTD, ESW - GERMANY, SEAH STEEL - KOREA, LALIT PIPES LTD, TATA STEEL, SOSTA STAINLESS PIPES, REMI GROUP.

Request for Our Latest Prices on Alloy 600/625, Inconel 600/625 Seamless and Welded Pipes, Tubes and Tubing!!!

Our Alloy 600/625 tube products can be offered in seamless, welded or welded and cold drawn form, depending on the alloy you require. Our Alloy 600/625 seamless and welded tubes size range starts at 1/2” NB or OD size and goes up to 6″ NB and OD.

We can offer Nickel Alloy 600/625 Tubing in random lengths of up to 6meters long or cut to a specific length as ordered. Inconel pipes and tubes are largely used for piping in Chemical Industry, Pulp, & Paper Manufacturing, Heat Exchangers, Process Piping.

Alloy 600 or Inconel 600, is one of the most popular high temperature alloy and is commonly identified as UNS N06600. Inconel 600 is a non-magnetic nickel-chromium alloy, with features of excellent corrosion resistance and mechanical properties, in addition to good weldability under a wide range of temperatures.

Inconel 601 is a nickel-chromium alloy, with an addition of aluminum, which exhibits excellent resistance to high temperature oxidation. The addition of aluminium allows it to demonstrate high mechanical properties even in extremely hot environments.

Inconel 625 is a nickel-chromium-molybdenum alloy, with addition of niobium that acts with the molybdenum to strengthen the alloy’s matrix, resulting in outstanding strength and toughness. Inconel 625 offers high resistance to pitting and crevice corrosion, making it a ideal alloy in chemical processing, marine engineering, oil and gas, and offshore industries.

Inconel 718 is a precipitation-hardenable nickel-chromium alloy, with higher levels of iron, molybdenum, and niobium as well as smaller contents of titanium and aluminium. Used in steam turbines, acid environments, and nuclear engineering, Alloy 600 exhibits high yield strength, and creep-rupture properties at high temperatures.

Alloy 600/625 seamless pipes and tubing’s are available in both OD and NB sizes. In addition to standard sizes, which are available in stock, our specialty is to manufacture and supply custom size Alloy 600 cold drawn seamless tubing’s from our factory.

Specifications for Inconel Alloy 600/625 Seamless Pipes, Alloy 600/625 Tubing’s, UNS N06600, UNS N06625

|

|

Seamless Pipe / Tubing |

Welded Pipe / Tubing |

|

Inconel 600 |

ASTM B 167 / 163 |

ASTM B 517 / 516 |

|

|

ASME SB 167 / 163 |

ASME SB 517 / 516 |

|

Inconel 601 |

ASTM B 167 |

ASTM B 167 |

|

|

ASME SB 167 |

ASME SB 167 |

|

Inconel 625 |

ASTM B 444 / 444 |

ASTM B 705 / 704 |

|

|

ASME SB 444 / 444 |

ASME SB 705 / 704 |

Inconel Alloy 600/625 Seamless Pipes, Alloy 600/625 Tubing’s, UNS N06600, UNS N06625 Supply, Stock Range

We can offer ex-stock supply of most of the standard size Inconel Alloy 600/625 alloy pipes and Inconel Alloy 600/625 tubes. Custom size (thickness x OD) Alloy 600/625 pipes can be offered with short delivery times to meet the most demanding requirements of our customers.

|

Products |

OD |

WT |

Length |

|||

|

Inch |

MM |

Inch |

MM |

Ft max. |

Mt max. |

|

|

Alloy 600/625 Tube |

1/2’’-3’’ |

12.0-76.2 |

0.02’’-0.5’’ |

0.5-12.0 |

105’ |

32.00 |

|

Alloy 600/625 Pipe |

NPS1/2’’-6’’ |

21.34-168.3 |

Sch10-Sch80 |

2.11-12.7 |

98’ |

30.00 |

Inconel Alloy 600/625 Seamless Pipes, Alloy 600/625 Tubing’s, UNS N06600, UNS N06625 Chemical Composition %

|

Alloy 600 |

Ni + Co |

Cr |

Fe |

C |

Mn |

S |

Si |

Cu |

|

72.0 min |

14.0-17.0 |

6.0-10.0 |

.15 max |

1.00 max |

.015 max |

.50 max |

.50 max |

|

|

|

|

|

|

|

|

|

|

|

|

Alloy 601 |

Ni |

Cr |

Al |

C |

Mn |

Si |

Fe |

|

|

61.5 |

22.5 |

1.4 |

0.05 |

0.3 |

0.2 |

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Alloy 625 |

Cr |

Ni |

Mo |

Co + Nb |

Ta |

Al |

Ti |

C |

|

20.00-30.00 |

Remainder |

8.0-10.0 |

1.0 max |

3.15-4.15 |

.40 max |

.40 max |

.10 max |

|

|

Fe |

Mn |

Si |

P |

S |

|

|

|

|

|

5.0 max |

.50 max |

.50 max |

.015 max |

.015 max |

|

|

|

Inconel Alloy 600/625 Seamless Pipes, Alloy 600/625 Tubing’s, UNS N06600, UNS N06625 Physical, Mechanical Properties

|

|

Inconel 600 |

Inconel 601 |

Inconel 625 |

Inconel 718 |

|

Density |

8.4 g/cm³ |

8.1g/cm³ |

8.4 g/cm³ |

8.2 g/cm³ |

|

Melting Range,℃ |

1370-1425 ℃ |

1320-1370℃ |

1290-1350℃ |

1260-1340 ℃ |

|

Elongation % |

30min. |

30 min. |

30 min. |

30 min. |

|

Tensile strength – Mpa |

550min. |

650min. |

760min. |

965min |

|

Yield strength – Mpa |

240min. |

300min. |

345min. |

550 min. |

|

Brinell hardness (HB) |

≤195 |

≤220 |

≤220 |

≤363 |

Typical Applications of Inconel Alloy 600/625 Seamless Pipes, Alloy 600/625 Tubing’s, UNS N06600, UNS N06625

Inconel Super alloys such as Inconel 600, Inconel 601, Inconel 625 and Inconel 718 are widely used by the chemical processing, pulp and paper, aerospace, power generation, food processing, nuclear engineering and heat treating industries.