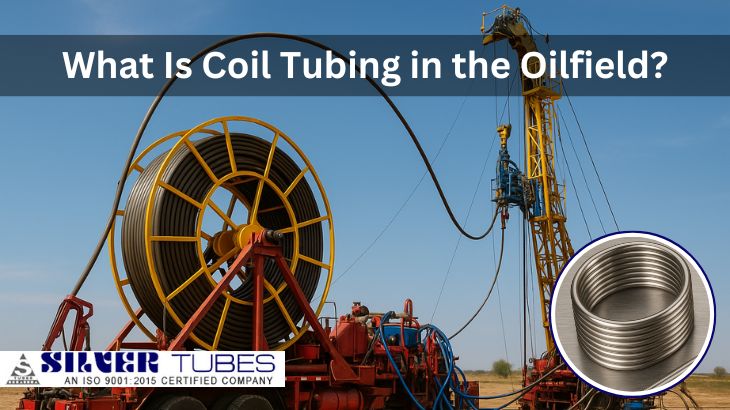

Coil tubing refers to a continuous length of small-diameter, high-strength steel pipe wound on a spool. It is widely used in oilfield services, particularly for well intervention and servicing operations, where it allows for continuous, pressure-controlled access to the wellbore. Unlike traditional drill pipe that comes in segments, coil tubing is seamless, flexible, and can be inserted into the well without interrupting production.

At Silver Tubes, we manufacture and supply coil tubing made from high-quality stainless steel, duplex, and nickel alloys, engineered for demanding conditions in oil and gas fields worldwide.

Technical Structure and Sizes

Coil tubing typically ranges from 1 inch to 3.25 inches in diameter, with lengths extending up to 25,000 feet, depending on the application. The pipe is stored and transported on large reels and can be spooled directly into the well using specialized equipment mounted on coiled tubing units (CTUs).

-

Standard Sizes: 1″, 1.25″, 1.5″, 2″, 2.375″, and 2.875″

-

Wall Thickness: Customizable from 0.083″ to 0.156″

-

Grades Available: SS 304/304L, 316/316L, Duplex 2205, Inconel 625/825, Hastelloy C276

Applications of Coil Tubing in Oilfield Operations

1. Well Intervention

Coil tubing is frequently used in remedial work where traditional tubing is impractical. It enables quick access for performing cleanouts, acid stimulation, or plugging operations in producing wells.

2. Circulation and Well Cleaning

It facilitates the circulation of fluids such as brine, water, or nitrogen into the wellbore to remove sand, scale, or wax buildup and restore well performance.

3. Acidizing and Hydraulic Fracturing

Coil tubing is used to pump acid or fracturing fluids directly into the formation to improve flow characteristics and boost hydrocarbon recovery.

4. Logging and Perforation

Coil tubing is capable of running wireline tools and sensors into the wellbore for data acquisition (real-time logging), as well as for conveying perforation guns to open new zones.

5. Fishing Operations

When tools or equipment become stuck inside a wellbore, coil tubing is deployed with specialized retrieval tools to recover lost equipment, minimizing downtime.

6. Drilling and Milling

With the integration of downhole motors, coil tubing can be used for underbalanced drilling or for milling operations like removing scale, plugs, or casing restrictions.

7. Nitrogen Lifting and Gas Injection

For wells with low productivity, nitrogen is injected through coil tubing to lift fluids and initiate or boost production flow.

Advantages of Coil Tubing Technology

-

Live Well Servicing: Enables work to be performed on pressurized wells without killing the well.

-

Time-Efficient: Faster deployment compared to jointed pipe systems.

-

Cost-Effective: Reduces operational time and overall servicing costs.

-

Versatile: Can be used in vertical, deviated, and horizontal wells.

-

Safe Operation: Lowers the risk of blowouts or pressure loss during intervention.

Silver Tubes – Trusted Coil Tubing Supplier in India

As a specialist manufacturer and exporter, Silver Tubes delivers coil tubing designed to meet the rigorous standards of global oil and gas operations. Our tubing is manufactured in accordance with:

-

ASTM A269 / A213 / A789

-

API 5ST specifications

-

NACE MR0175 compliance for sour service environments

We supply coil tubing with high fatigue resistance, uniform mechanical strength, and excellent corrosion resistance—suitable for harsh and corrosive drilling fluids, H₂S environments, and CO₂ exposure.

We provide options in:

-

Stainless Steel Coil Tubing

-

Duplex and Super Duplex Coil Tubing

-

Nickel Alloy and Inconel Coil Tubing

Conclusion

Coil tubing has revolutionized oilfield operations by enabling efficient, safe, and cost-effective interventions without interrupting production. From well cleaning and acid stimulation to fishing and milling, it provides a versatile solution across upstream processes. With technological advancements and increasing global energy demand, the use of coil tubing will only continue to grow.